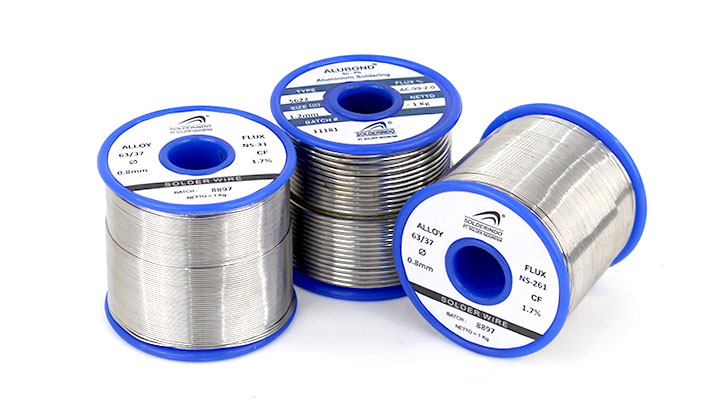

HOZAN LEAD FREE SOLDER (0.8mm/400g) Hozan HS-313

SKU= HOZAN-HS-313

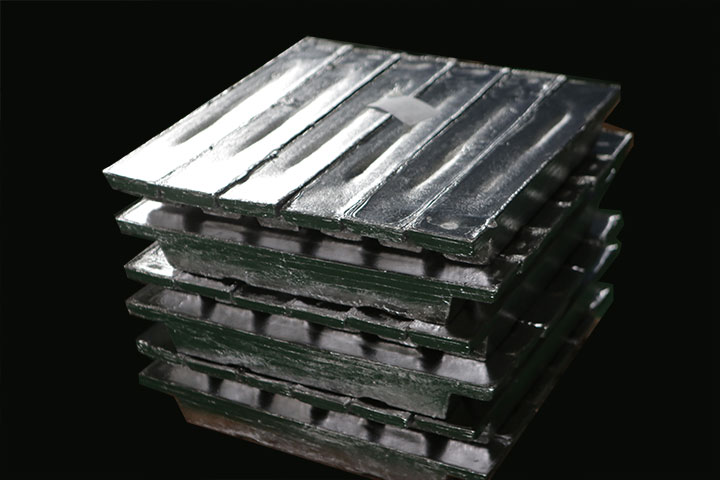

This is lead-free solder containing 3% silver.

This alloy is recommended by JEITA and has been used since the early days

of the lead-free revolution, making it a highly reliable and proven solder.

Item Description:

|

Brand: |

HOZAN |

|

Item Name: |

Lead Free Solder |

|

Part Number: |

HS-313 |

|

Size: |

Melting point: 217-220℃ Length (reference value): 130m Wire diameter (mm): 0.8 Lead-free solder compatible: Compatible Weight (g): 400 Components (%): Ag3/Sn96.5/Cu0.5 |

|

Weight: |

400g |

|

Other Details: |