Circuitworks CW8400

Lagunastar PN. CHEM-CW8400

Lead-Free Flux Pen - 9 g (0.32 oz.)

A pen for applying lead-free flux with precision and control.

·

Applies a

noncorrosive, halide free, no clean flux for high temperature, lead-free

application

· Can also be used for

tin/lead fluxes

· Flux meets Bellcore

TR-N-NWT-000078 and IPC SF-818 for Surface Insulation Resistance

· Flux meets ANSI / IPC

J-STD-004, Type ROL0

· Easily removed with

Lead-Free Flux Remover Pen, or Flux-Off® Lead-Free Flux Remover

· Excellent material

compatibility

·

Fast drying

CircuitWorks Flux Pens

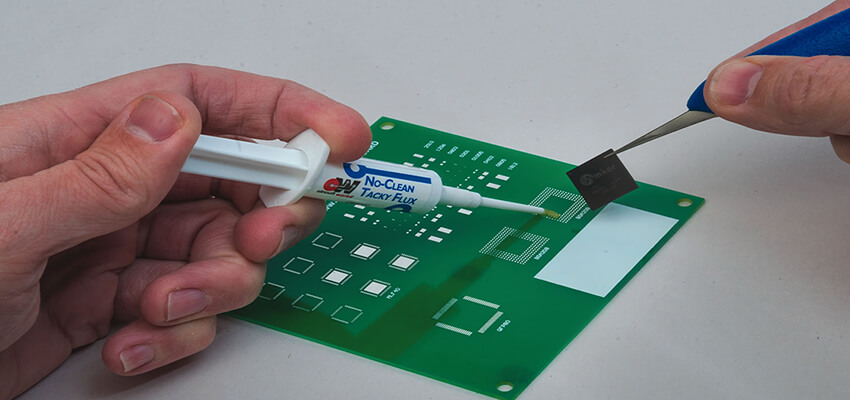

CircuitWorks Flux Dispensing Pens provide controlled and exact applications that are generally compatible with most materials in the electronics industry. Dispense flux on printed circuit boards, heat sinks, chip carriers, switches, sockets and much more.

CircuitWorks Flux Dispensing Pens are fast drying, completely portable and have minimal excess flux waste. Instant wetting action provides thorough deoxidation of metallic surfaces providing the best possible surfaces for hand soldering.

CircuitWorks Flux Pens are designed specifically to apply each type of flux with precision control:

- Lead-Free Flux Dispensing Pen quickly applies a noncorrosive, halide-free, No Clean flux which meets Bellcore TR-NWT-000078 and passes IPC SF-818 for surface insulation resistance.

==

notes:

1. TDS

==

notes:

1. CircuitWorks CW8400 is a flux pen from Chemtronics. It's a tool used in the electronics industry for applying flux to circuit boards during the soldering process. Here are some key features and uses:

Easy Application: The CW8400 Flux Pen is designed like a marker for easy application of flux. It allows for precise control when applying flux to intricate circuits.

High Quality Flux: The pen contains high quality, no-clean flux that promotes good soldering and can be left on the board without cleaning.

Versatile: It's suitable for a variety of applications, including rework and touch-up soldering, and can be used on chip carriers, heat sinks, SMT pads, tab bonding, and more.

Safe for Electronics: The flux is non-corrosive and non-conductive, making it safe for use on sensitive electronics.

Portable: The pen-like design makes it easy to carry and use anywhere.

Remember to use the CW8400 Flux Pen in a well-ventilated area and avoid contact with skin and eyes. Always follow the manufacturer's safety instructions when using this product.

2.

Ang CW8400 Flux Pen ay ginagamit sa industriya ng elektronika para sa pag-aapply ng flux sa mga circuit board sa panahon ng proseso ng pagso-solder. Narito ang ilang mga lugar kung saan ito karaniwang ginagamit:

Rework at Touch-up Soldering: Ginagamit ang CW8400 Flux Pen para sa mga pagkakataon ng pag-aayos o pagbabago sa mga solder joint na kailangan ng dagdag na flux.

SMT (Surface Mount Technology) Pads: Ang flux pen ay ginagamit upang magdagdag ng flux sa mga SMT pads bago ang soldering process. Ito ay makakatulong sa pagpapabuti ng adhesion ng solder paste.

Chip Carriers: Sa mga pagkakataon ng pag-aayos o pagbabago ng mga chip carrier, ang flux pen ay ginagamit upang magdagdag ng flux sa mga solder joint upang matiyak ang tamang pagkakabit.

Heat Sinks: Kapag nagso-solder ng mga heat sinks, ang flux pen ay ginagamit upang magdagdag ng flux sa mga solder joint upang matiyak ang maayos na pagkakabit at pagpapabuti ng thermal conductivity.

Tab Bonding: Sa mga pagkakataon ng pag-aayos o pagbabago ng mga tab bonding, ang flux pen ay ginagamit upang magdagdag ng flux sa mga solder joint upang matiyak ang tamang pagkakabit at koneksyon.

Mahalagang tandaan na dapat gamitin ang CW8400 Flux Pen sa isang maayos na bentilasyon at iwasan ang direktang pagkontak sa balat at mata. Sundin palagi ang mga tagubilin sa kaligtasan mula sa tagagawa kapag ginagamit ang produktong ito.